Cheap Shingles Chinese roofers are using… Examining the Impact on Quality and Standards

Cheap shingles from China have sparked debate in the roofing industry. Some worry these Chinese shingles could harm the market’s quality standards. Others see them as a way to offer more affordable options to customers. But are these products even comparable to what we produce here in Canada?

The impact of low-cost Chinese shingles on the roofing industry is mixed. While they provide budget-friendly choices, concerns exist about their durability and long-term performance. This has led many roofing contractors to question whether using these materials is wise. This has been a long-standing debate since 2015 when the shingles from China first began appearing on the market and did NOT pass Canadian quality control!

Can Chinese shingles even be compared to Canadian Shingles?

On June 17th, 2015, Alec Caldwell a writer for the Contractor published an article titled “Just what our industry needed next: Cheap, crappy Chinese shingles” He points out that container loads of Chinese asphalt shingles arriving in Canada are way below the quality Canadian manufacturers have to follow under CSA standards.

According to Canadian standards, asphalt shingles have to be made or constructed in a certain way to survive climate change. Each bundle should weigh around 79 lbs, not the 50-something lb bundle weights that these imported imposters weigh.

“Homeowners are really being duped if they choose the lowest price in town, especially when the competition is undercutting by the $1,000’s. If this occurs, bets are imported shingles are being installed and forget about warranties on the product.“

The influx of Chinese roofing products has changed the landscape for both contractors and homeowners. It’s created new competition in the market, forcing established brands to adapt. As the debate continues, the industry must balance cost savings with maintaining high standards for roofing materials.

Impacts on the Roofing Industry

Cheap shingles from China have caused ripples across the Canadian roofing industry. Roofing contractors need help deciding between quality and cost savings.

These low-priced materials have disrupted traditional supply chains. Some roofers opt for cheaper options to stay competitive, while others stick to premium products.

Material costs have shifted dramatically. Chinese shingles often come at a fraction of the price of North American alternatives. This price gap puts pressure on local manufacturers.

Labour costs remain largely unchanged. Skilled roofers still command similar wages regardless of shingle origin.

Inflation has complicated matters further. Rising prices in other areas make cheap shingles more appealing to budget-conscious customers.

Market research shows mixed reactions. Some homeowners embrace the cost savings, while others worry about long-term durability.

The industry faces a balancing act. Quality concerns compete with the need to offer affordable options. This tension shapes current market dynamics. At what point do Chinese shingles become worth the cost savings if they don’t last as long?

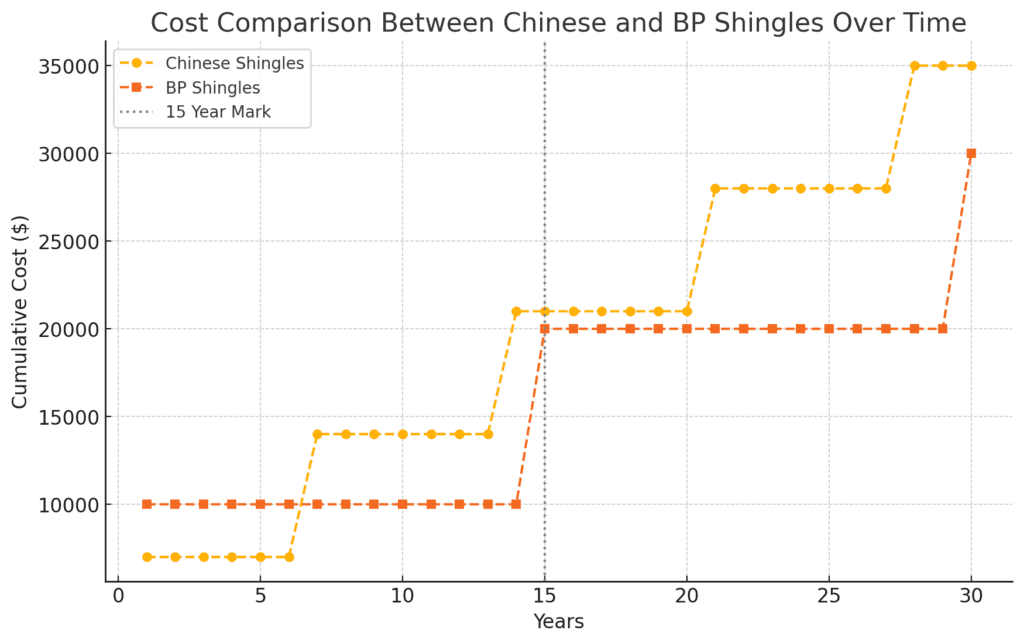

Cost Comparison of Chinese Shingles to BP Shingles

Assume you pay $7000 instead of $10,000 for a new roof from a Chinese installer. If you have to replace your roof in half the lifespan then if you installed it from a reputable brand, your costs over 30 years is double!

Roofing businesses must adapt to survive. Some focus on premium installations, while others incorporate cheaper materials into their offerings.

Material Considerations

Roofing materials play a key role in the quality and longevity of roofs. The choice of materials affects durability, cost, and availability.

Asphalt Shingle Quality

Asphalt shingles remain a popular roofing choice in Canada. Higher-quality shingles tend to last longer and resist harsh weather better. Some cheap shingles may not meet Canadian standards for durability.

Top-tier shingles use more asphalt and stronger fibreglass mats. This makes them heavier and more resistant to wind and impacts. Lower-grade options often have less asphalt and thinner mats.

Shingle colour can also affect roof life. Darker shingles absorb more heat, which may lead to faster breakdown in hot climates.

Metal Roofing Comparison

Metal roofs offer a durable alternative to asphalt shingles. They tend to last longer, with some lasting 50 years or more.

Common metal roofing materials include:

- Steel (galvanized or painted)

- Aluminum

- Copper

- Zinc

Metal roofs cost more upfront but may save money long-term. They resist fire, wind, and impact better than many other materials.

These roofs also reflect more sunlight, which can lower cooling costs in summer. But metal roofs can be noisy during rain or hail storms.

Supply Chain Shortages and Material Availability

Recent years have seen issues in the global supply chain for roofing materials. This has led to higher prices and longer wait times for some products.

Factors affecting supply include:

- Factory shutdowns

- Shipping delays

- Raw material shortages

- Labour shortages

These issues have hit both asphalt shingles and metal roofing. Some roofers have had to switch brands or delay jobs due to a lack of materials.

Local sourcing of materials may help reduce some of these problems. However many roofing products still rely on global supply chains.

Regulatory and Standards Compliance

Roofing practices in Canada are governed by strict rules and standards. These regulations aim to ensure safety, durability, and quality in both residential and commercial roofing projects.

Building Codes and CSA Standards

Building codes across Canada set clear rules for roofing. They spell out what materials can be used and how roofs must be built. The Canadian Standards Association (CSA) creates guidelines for roofing products. These standards make sure shingles and other materials are safe and long-lasting.

Roofers must follow local building codes when working on homes or businesses. They need to use CSA-approved products. This helps protect buildings from leaks and weather damage. It also keeps people safe from weak or faulty roofs.

Look for the CSA stamp on your bundles of shingles to see if you’re getting COUNTERFEIT SHINGLES!

Impact of Substandard Roofing Practices

When roofers cut corners or use poor-quality materials, it can cause big problems. Cheap shingles might not last as long as they should. This can lead to leaks and damage to homes and businesses. It also means owners have to replace their roofs more often.

Bad roofing work can be unsafe. It might not hold up in strong winds or heavy snow. This puts people at risk. It can also drive up insurance costs for everyone. When some roofers do shoddy work, it makes the whole industry look bad. This can make it harder for good roofers to find work and earn a fair wage.

Labour and Trade Expertise

The roofing industry faces challenges in workforce development, recruitment, and skill retention. These issues impact the quality and availability of roofing services across North America.

Education and Training Deficits

Many roofing companies struggle to find workers with proper training. Vocational schools often lack specialized roofing programs. This gap leaves new hires without key skills. On-the-job training becomes crucial but takes time and resources.

Some firms partner with trade schools to create roofing courses. These programs teach safety, material knowledge, and installation techniques. Graduates enter the workforce better prepared. Still, more education options are needed to meet industry demands.

Labour Shortages in North America

The construction sector, including roofing, faces ongoing worker shortages. An aging workforce and limited interest from younger generations contribute to this problem. In Canada, some regions report a lack of qualified roofers.

This shortage leads to longer wait times for roofing projects. It can also result in rushed work or the use of less skilled labour. Some companies turn to temporary foreign workers to fill gaps.

Impacts of Labour Shortages:

- Delayed projects

- Higher labour costs

- Potential quality issues

Employee Referrals and Skill Acquisition

Many roofing companies rely on employee referrals to find new workers. Existing staff often bring in friends or family members. This approach can help build a loyal workforce. It also allows for informal skill sharing among teams.

Apprenticeship programs play a key role in skill development. Experienced roofers mentor newcomers, passing on valuable trade knowledge. This hands-on learning is vital for mastering complex roofing techniques.

Some firms offer incentives for successful referrals. This can include bonuses or other perks. The goal is to attract skilled workers and reduce turnover rates.

Effective Project Management

Project management is key to successful roofing jobs. Good planning and problem-solving help finish work on time and within budget. New tools and methods can boost efficiency and quality.

Future of the Roofing Industry in North America

The roofing industry in North America is set for significant changes. New technologies and materials are emerging, promising more durable and energy-efficient roofs. These innovations will likely reshape the market in the coming years.

Climate change is driving demand for resilient roofing solutions. Homeowners and businesses are looking for products that can withstand severe weather events. This trend is pushing manufacturers to develop stronger, more weather-resistant materials.

The construction sector is embracing sustainable practices. Green roofing options, such as solar tiles and cool roofs, are gaining popularity. These eco-friendly choices may become standard in new home builds and roof replacements.

Labour shortages continue to challenge the industry. Many experienced roofers are retiring, creating a skills gap. Training programs and apprenticeships will be crucial to maintain a skilled workforce.

Supply chain disruptions have affected material availability and costs. The industry is adapting by diversifying suppliers and exploring local production options. These strategies aim to reduce dependence on foreign imports and stabilize prices.

Digitalization is transforming roofing businesses. Drones for roof inspections and software for project management are becoming common tools. These technologies can improve efficiency and accuracy in roof assessments and repairs.

The aging housing stock in North America will drive demand for roof replacements. This presents opportunities for growth in the residential roofing market. Contractors who can offer quality services and materials will likely see increased business.

Frequently Asked Questions

The roofing industry faces several challenges and considerations. Quality materials, proper installation, and regular upkeep play key roles in roof longevity and performance.

What significant challenges are prevalent in the roofing industry?

Labour shortages pose a major hurdle for roofing companies. Many struggle to find skilled workers to meet demand. Rising material costs also cut into profit margins.

Weather delays can throw off project timelines. Extreme heat, rain, and snow make roofing work unsafe at times.

Which factors contribute most to roofing damage?

Harsh weather takes a toll on roofs. High winds can lift and tear off shingles. Heavy snow loads stress the roof structure. Hail impacts can crack or dent roofing materials.

Poor attic ventilation traps heat and moisture. This speeds up shingle aging and can lead to rot in the roof deck.

What roofing material offers a balance between cost and durability?

Asphalt shingles remain a popular choice for their mix of affordability and performance. They come in various grades with different lifespans. Higher-end options can last 30 years or more.

Metal roofing costs more upfront but lasts longer. It resists fire, wind, and impacts well.

How does the use of substandard materials impact the roofing sector?

Low-quality shingles wear out faster. This leads to more frequent repairs and replacements. Homeowners lose trust in roofing companies when their new roof fails early.

Cheap materials can void manufacturer warranties. This leaves customers without protection if issues arise.

What considerations should be made when choosing a roofing contractor?

Look for proper licensing and insurance. Ask for local references and examples of past work. Get detailed written estimates from multiple companies. C.D. Roofing & Construction Ltd. has been in business since 1995 and is one of the most recognized roofing companies in the Durham Region!

Ask about our warranty terms and legendary after-service support.