Problems With Synthetic Roof Underlayment in the Durham Region

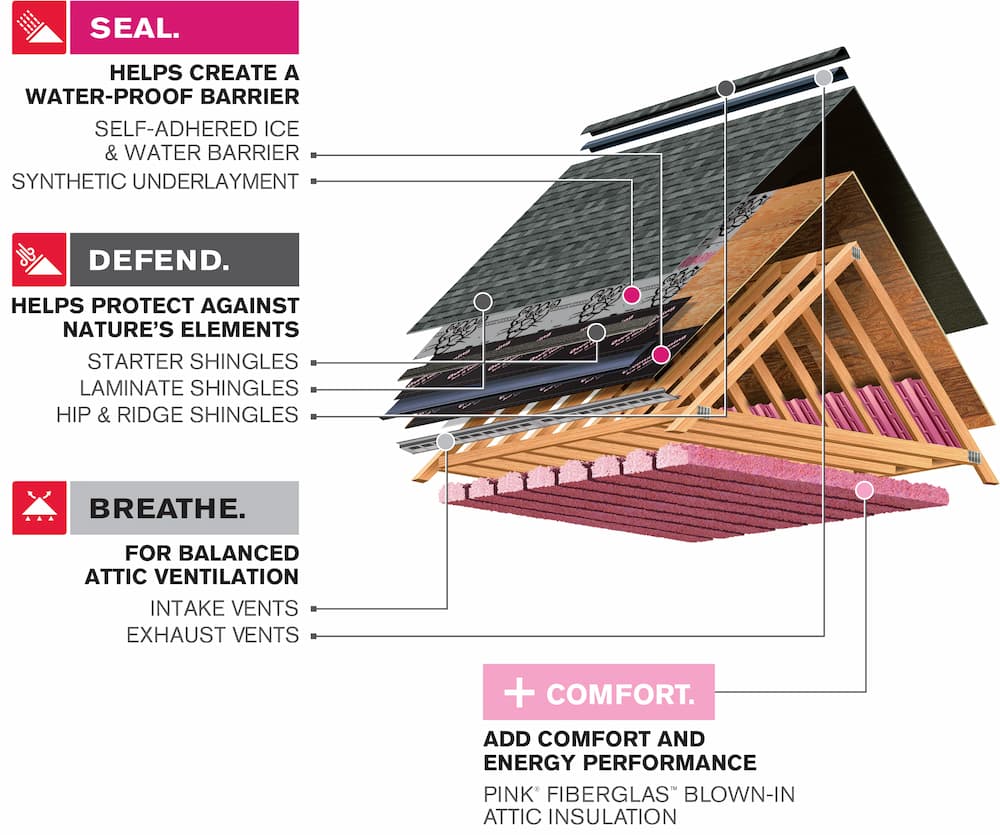

To have a successful roofing system, you must install quality parts that function correctly. When you use low-quality materials or fail to prioritize steps in installation, you reduce the lifespan of your roof. Roofing underlayment should be your concern to increase the longevity and quality of your roofing system. Various roofing underlayments are available; most people prefer synthetic underlayments. Despite there being a few problems with synthetic roof underlayment, it’s considered the most popular choice in the roofing industry today.

Synthetic underlayment provides superior performance compared to other materials. The synthetic underlayment’s durability and longevity have made it the recommended roof underlayment today.

This post will walk you through the major problems with synthetic roofing underlayment. This will help you understand the type of projects that synthetic underlayment is unsuitable for in the roofing industry. This article should give you enough insight into making an informed decision for your roofing repair and/or installation project.

Synthetic Roof Underlayment

Synthetic roof underlayment is a polyethylene plastic roofing accessory widely used in the roofing industry. It may also be made of laminated polypropylene material. The synthetic roof underlayment is always placed over the deck of the roof. When the accessory is installed, it provides an extra protection layer from different elements in the roof.

The synthetic roof underlayment is water-repellent with excellent performance. This makes it the best material of choice when it comes to keeping a roof dry (and everything underneath it). The synthetic roof underlayment has also proven to be more resistant to different kinds of damage when exposed. For instance, the material can remain undamaged when exposed to different elements for a specific time.

The timeframe a synthetic roof underlayment can take before getting damaged depends on the manufacturer. For instance, synthetic roof underlayment materials from Sharkskin roofing underlayment can survive damage from six months to 12 months when exposed to different elements.

(Click here to find out how long it takes to replace a shingle roof)

Advantages of using a synthetic roof underlayment

Easy installation process

Because the synthetic material is lightweight, it is much easier to install and safer to handle during installation. It also helps that the rolls are much larger (cover 1000 sq feet compared to a felt roll at 300-400 sq. feet). This makes the job faster by reducing the number of times you go back for a new roll of material.

Resistance to different weather conditions

The synthetic material is resistant to damage coursed by water, mildew, or even mould. This makes it have a longer lifespan. It also repels water much more effectively making your home safer in the event any shingles blow off of your roof.

(Click here to read about how long a shingle roof lasts in Ontario!)

Enhanced walkability & durability

The ability of this underlayment to withstand more pressure than felt prevents tears and rips. This saves roofers the time of replacing ripped segments from walking over the lining. While the cost of material is higher than the felt alternative, homeowners may get some relief in the cost spent on installation.

Synthetic underlayment problems that affect your project

It’s easy to understand why most people prefer using the synthetic option for their roofing. As promised, you’re now going to learn the common problems with synthetic roof underlayment when it comes to your roof. We came up with three major problems you should know about.

Synthetic roofing underlayments are more expensive

Due to the fact that synthetic roof underlayment is a high-quality material, it comes at a much higher price than its felt counterpart. Non-adhesive synthetic roof underlayment is priced between 17 to 25 cents per foot. As for self-adhering underlayment, the cost is between 50 to 75 cents per foot.

On the other hand, an ordinary felt roof underlayment is priced between 5 to 10 cents per foot. These are general price estimates, but from these examples, you can see the wide gap in the prices.

Be wary of low-quality manufacturers

Not all synthetic roofing underlayments are created equal. There is a big difference between high-quality brands and low-quality brands in the market. For this reason, you will have to be more attentive when purchasing to ensure you get the best material for your roof.

Great marketing tactics can lure you into buying low-quality synthetic underlayment, thinking it’s the best brand. The best way to identify a high-quality brand of synthetic roof underlayment is by going with its weight. A quality underlayment will have more weight NOT just a thicker mil layer.

Some companies will cheap out on the material with a fuzzy top layer. This will give the appearance of thickness but not perform as well as a brand that’s heavier.

Some building codes prohibit the Use of Synthetic Roof Underlayment

Some buildings don’t allow the use of synthetic roofing underlayment. Due to this reality, take the extra step to check your building code to be sure whether or not you can opt for a synthetic underlayment. You can also ask your roofing contractor to confirm the building code, which will specify the type of underlayment you should use.

The takeaway…

Synthetic roofing underlayments have proved to perform the best when used in a roofing system. It provides the best walkability, high durability, and a longer lifespan. It’s also easy to install, however, just like any other material, there are problems with synthetic roof underlayment that you need to consider.

If you can get around the higher price point and it’s accepted by your building code, the synthetic option is your best choice.